Sep

16

2018

After I got everything taped up this week, my son and I tag-teamed painting it. While this Differential housing and cover are all aluminum with no risk to it rusting, we started off laying down a thing coat of POR-15 Rust Preventative Paint because it has superior adhesion to bare metals than the high-temp engine paints alone.

The instructions say to apply a second coat coat when it become tacky and can still be finger-dragged (rough 2-6 hours depending on...

Sep

09

2018

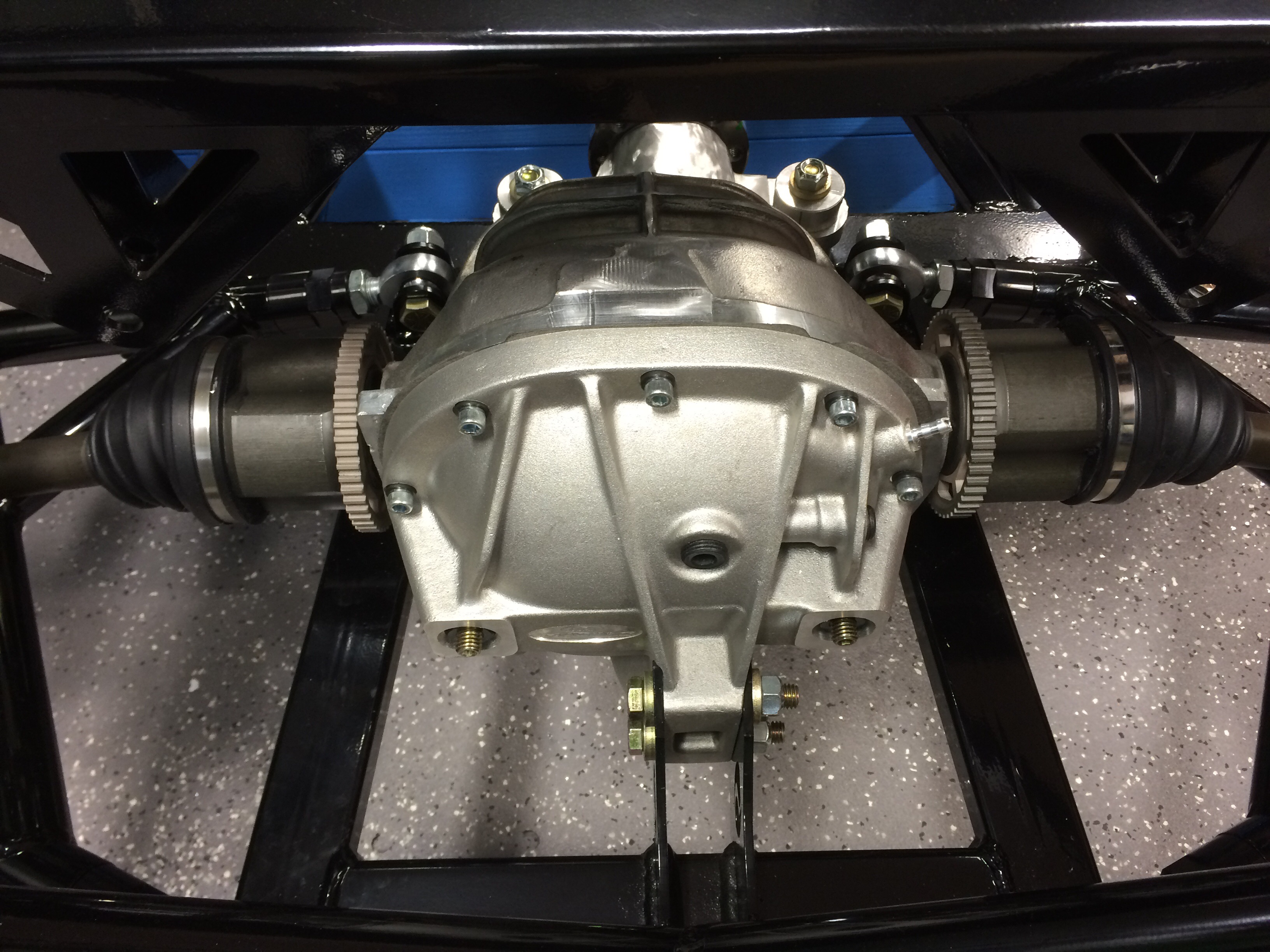

Decided to paint the IRS Differential Carrier after all. Since it's already installed in the car I've got my work cut out for me. This is going to be very tedious.

Spent a little time today prepping it with POR-15 degreaser and metal prep. The painting requires several coats and there isn't enough time to finish if I start now, so I'll wait until a day while I can do base and final coats all at once in one straight...

Aug

19

2018

I painted my T56 transmission and bellhousing this weekend. To tie everything into my car's planned color scheme I chose a mix of Ford Red, Black, and Silver. No, I couldn't keep it simple and paint it one color like everyone else... I had to go with three colors for two parts.

Here is a list of supplies used:

Duplicolor Gray Engine Primer with Ceramic - DE1612

Duplicolor Aluminum Engine Enamel with Ceramic - DE1615

Duplicolor Clear Top Coat...

Apr

16

2018

I put these tables together to illustrate how our chosen combination of driveline parts will perform. (more…)

May

18

2016

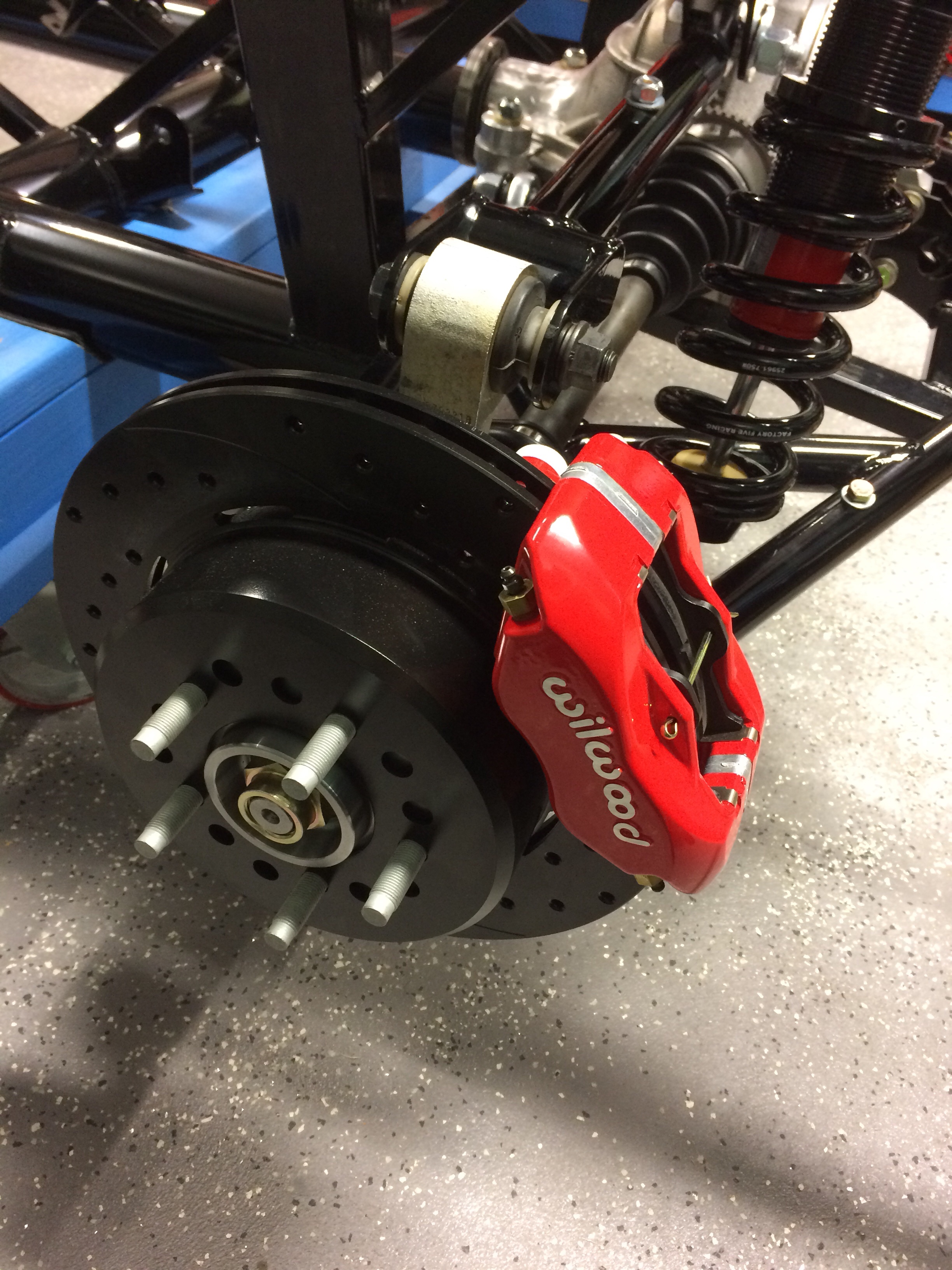

We installed the Cobra IRS knuckles, hubs, bearings, and rear Wilwood brakes tonight.

Dec

02

2015

Ford's 2nd gereation Coyote Engine Chosen For This BuildThe Ford Performance all-aluminum 2017 5.0L Coyote crate engine (M-6007-M50A) is a modern 5.0L 32-valve DOHC V-8 that uses advanced features like Twin Independent Variable Camshaft Timing (Ti-VCT) to deliver 435 horsepower @ 6500 rpm and 400 ft.-lb.+ of torque @ 4250 rpm (with premium fuel). The lightweight aluminum cylinder block features cross-bolted main bearing caps and thick main bearing bulkheads for bottom-end strength, optimized oil drainback and windage control to improve...

Apr

17

2015

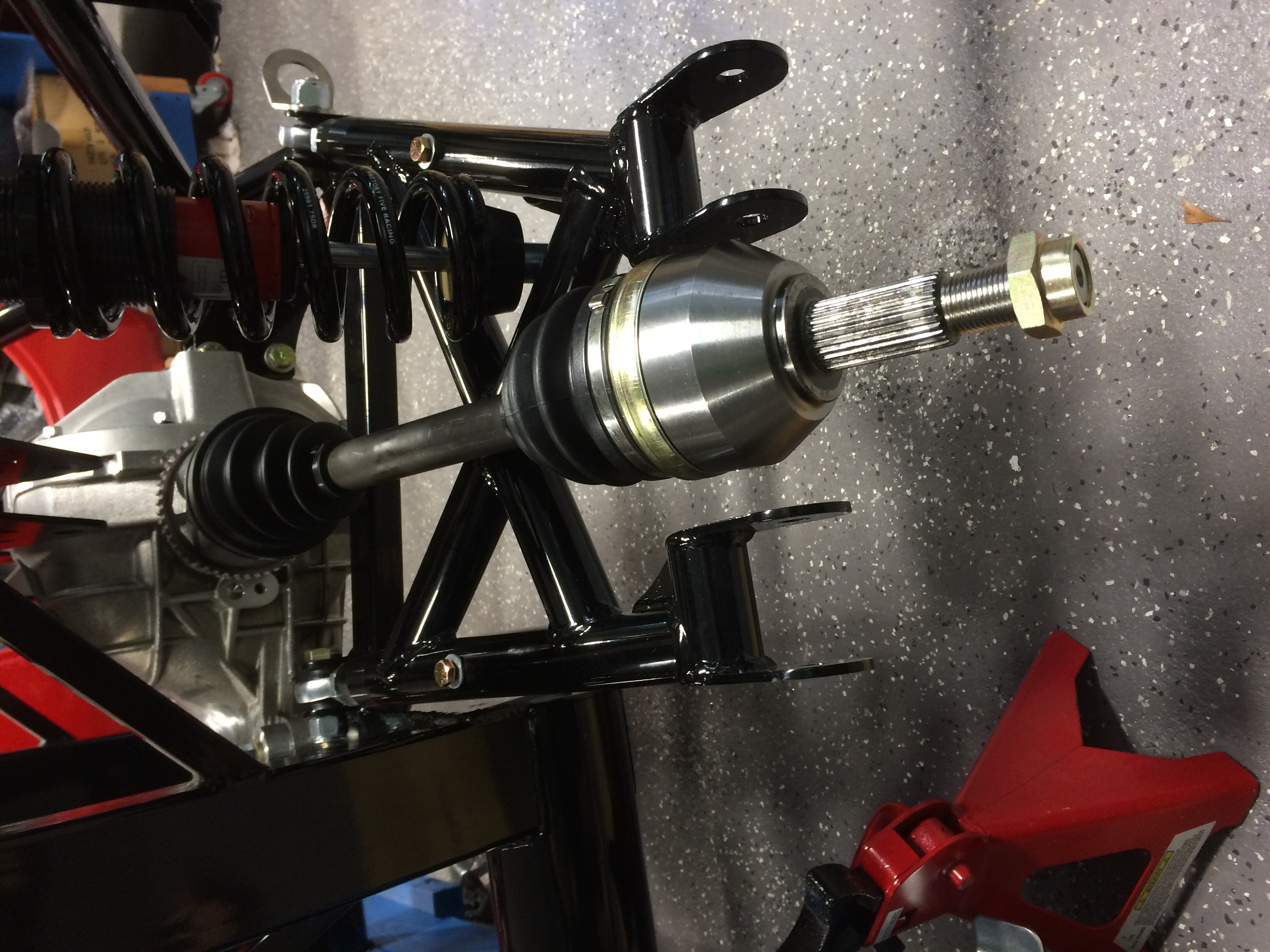

The IRS CV axles were installed, they fit, and to my surprise the c-clips engaged without issue. Others have reported engagement issue, but that wasn't the case here.

Apr

06

2015

Tonight Brad and I installed the rear ABS tone rings onto the rear IRS axles. It required heating the rings to a near-glow with a MAP torch to expand the inner openings, sliding them onto the axles, wait for them to cool and shrink onto the axle.

Feb

13

2015

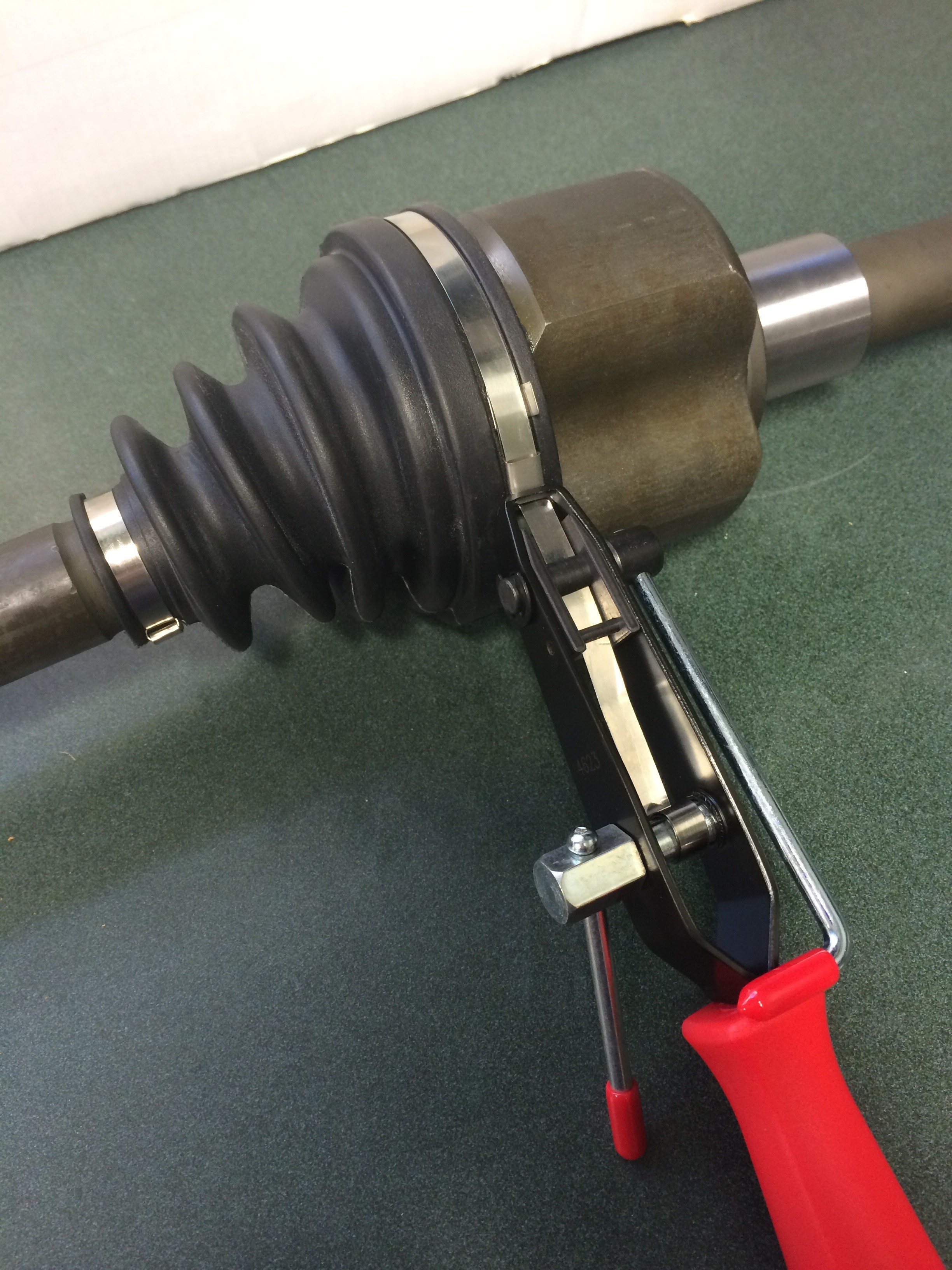

There was a tech bulletin issued for the FFR Rear CV Axles. Some people had problems with the lobes not being fully seated.

This required having to inspect them by removing the CV boots.

No problem. Everything looked good and I repacked the CV boots with grease. Only issue was I needed a special tool to button everything back up. A quick search on Amazon and I got on of these:

OTC 4623 CV Joint Banding Tool & Cutter.

Two days later...

Jan

21

2015

Per this thread, some people are reporting 2 issues with half shaft supplied by Factory Five with the complete Mark IV kit:

https://www.ffcars.com/forums/17-factory-five-roadsters/322145-cv-half-shaft-question.html#/topics/322145?page=2

Some report:

1. The half shafts are too short by approx 9/16"

2. The splines on the end that goes into the diff are not machined long enough for the shafts to seat properly and the circlip to engage before the spline's shoulder bottoms out

For those that had issues, the splines are only 1 1/2 " long, and the fix...

Recent Comments